Manufacturing Gladbeck - pressure vessels, heat exchangers, compressor parts, ball valves

Pressure vessels, heat exchangers, special vessels, service for pressure vessels

The BORSIG Process Heat Exchanger GmbH has decades of in-depth experience when it comes to planning, performing and implementing all different service tasks and specifications even under the most difficult conditions. Our Gladbeck/NRW service location is equipped with comprehensive manufacturing capacities. Following an expansion, we have 5,250 m² of manufacturing space, 32,000 m² of open ware-house space and manufacturing capacities of up to approx. 100 t.

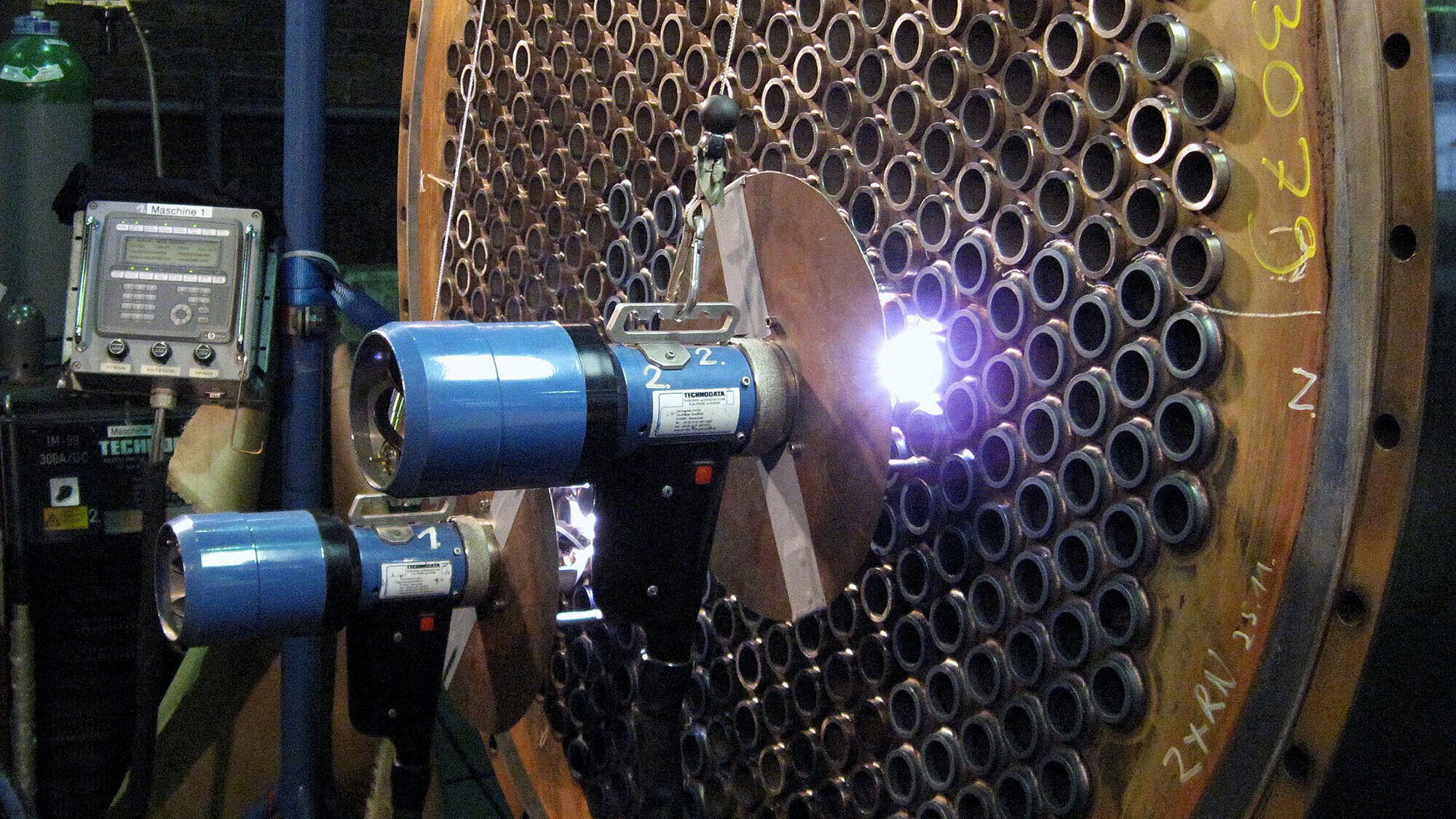

Our staff works at the highest level and guarantees constant superior and convincing quality through state of the art technology, innovative manufacturing processes and workshops and through their personal dedication. Our outstanding welding competency should also be highlighted.

- Electric manual welding

- TIG

- MIG

- MAG

- and UP welding for interior and exterior welding work

- weld cladding with ribbon and wire

- automatic tube welding including seamless implementations.

- Close-grained steel

- boiler steel, rust

- acid and heat resistant steel (including extreme temperatures)

- nickel-based alloys

Our inspection technology comprises X-ray, radionuclide, ultrasound, dye penentrant and magnetic particle inspections, hardness testing as well as PMI. We also offer metallography and damage analysis.

- DIN EN ISO 9001

- DIN EN ISO 14001

- AD 2000 HP0

- TRD 201

- DIN EN ISO 3834-2

- WHG § 19

- welder qualification following ASME

- China License of Special Equipment Pressure Vessels A1

- IBR

- Japanese Boilercode

- GOST-R

Pressure vessel manufacturing such as HP / MP / LP preheaters, sectional coolers, condensers, convection zone modules, reactors and other types of heat exchangers; servicing, field service and maintenance (including piping); maintenance of valves (large ball valves, valves and slides); single item production, machining and machine maintenance; supply of spare parts for BORSIG original and third-party products as well as technical advice to all of the above.

UP welding system for vessels up to a diameter of 4000 mm for interior and exterior welding work, weld cladding with ribbon and wire, UP welding system for welding in fittings, gas cutting machine, plasma cutter for material thicknesses of up to 50 mm, vessel turning system with a load capacity of up to 100 t, CNC turning machines, centre lathes, vertical cutting and boring machines, ball grinding machine up to 52“ and the like

Compressor valves, ball valves

BORSIG ValveTech GmbH has a modern machinery pool including among other things CNC machining centres for diameter up to 400 mm, CNC lathes for diameter up to 350 mm, a lapping machine for diameters up to 230 mm, a surface grinding machine, a blasting room, industrial washing machines; its manufacturing and storage premises are arranged on the area of 650 m².

Our spare parts warehouse is represented by almost 2,000 stock items and continuously expands its capacity by new ones, such as sinus spring plates, damper plates, valve plates, springs of various forms and dimensions as per customized requirements.

Our round steel material warehouse is represented by almost 1,000 items of various grades and diameters, which find continuous application on a daily basis.

- All conventional grades of stainless steel, e.g. 1.4021, 1.4301, 1.4571, 1.4462, …

- All common types of synthetic materials with glass fiber and carbon content, e.g. PTFE, PTFE carbon, ...

- reconditioning of valves

- manufacturing of new valves

- reconditioning of piston rod packings

- manufacturing of new piston rod packings

- manufacturing of new oil wiper packings

- manufacturing of individual and serial items

- supply of spare parts of BORSIG and of external vendors

- CNC milling

- CNC lathing

- software based interfaces for CNC programs (SOLID CAM / Inventor solution)

- tightness test of reconditioned valves with our pressurising device

- hydraulic test of water-cooled rod packing cases

- constructive advising for customized solutions.

- manufacturing of spare parts, such as ball and seat rings

- repair, refurbishment, modifications of safety valves, control valves, slides, flaps and drives