BORSIG Membrane Technology GmbH

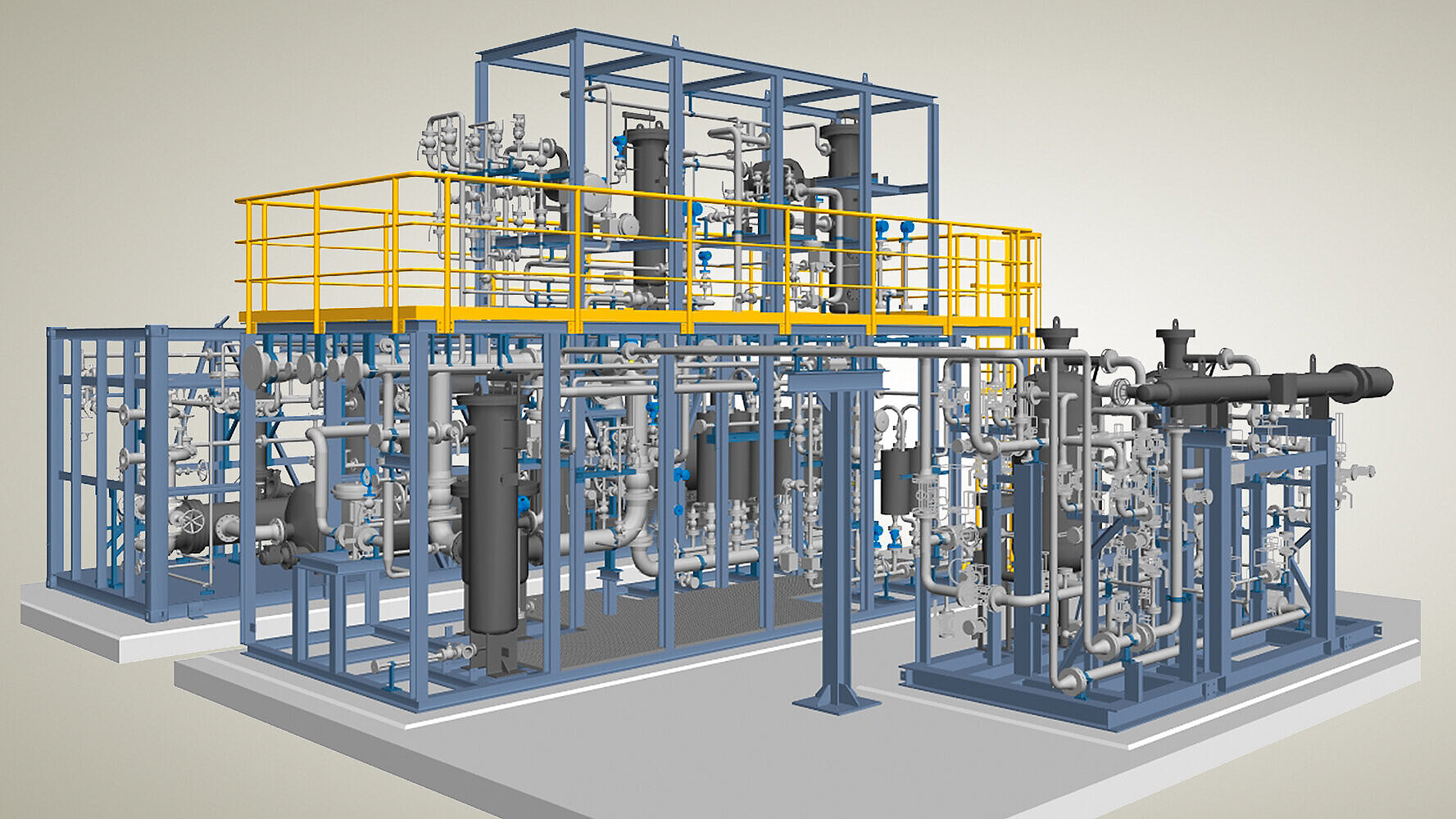

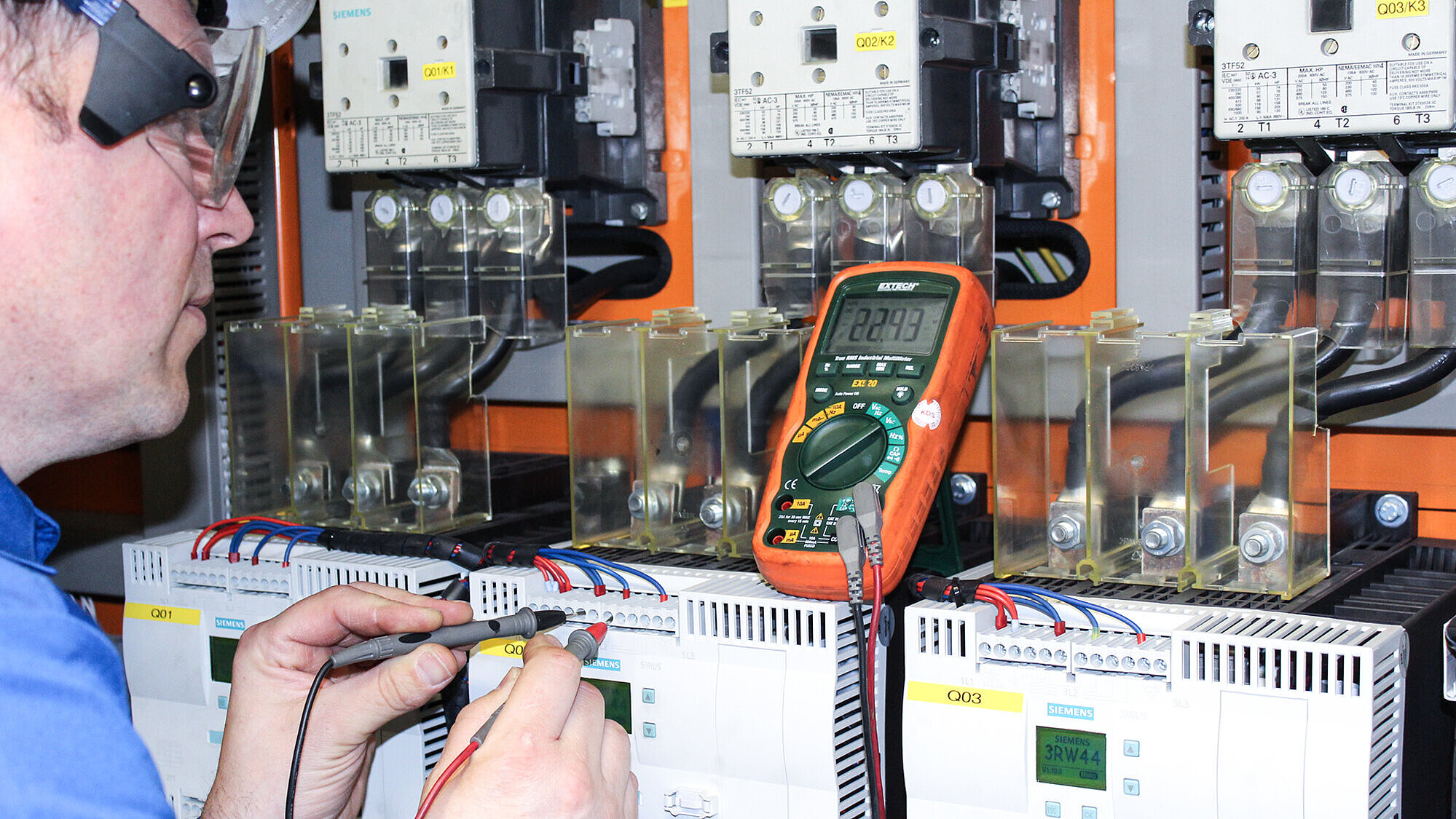

Service for

process and

membrane technology

Life-cycle-service for all phases of your projects.