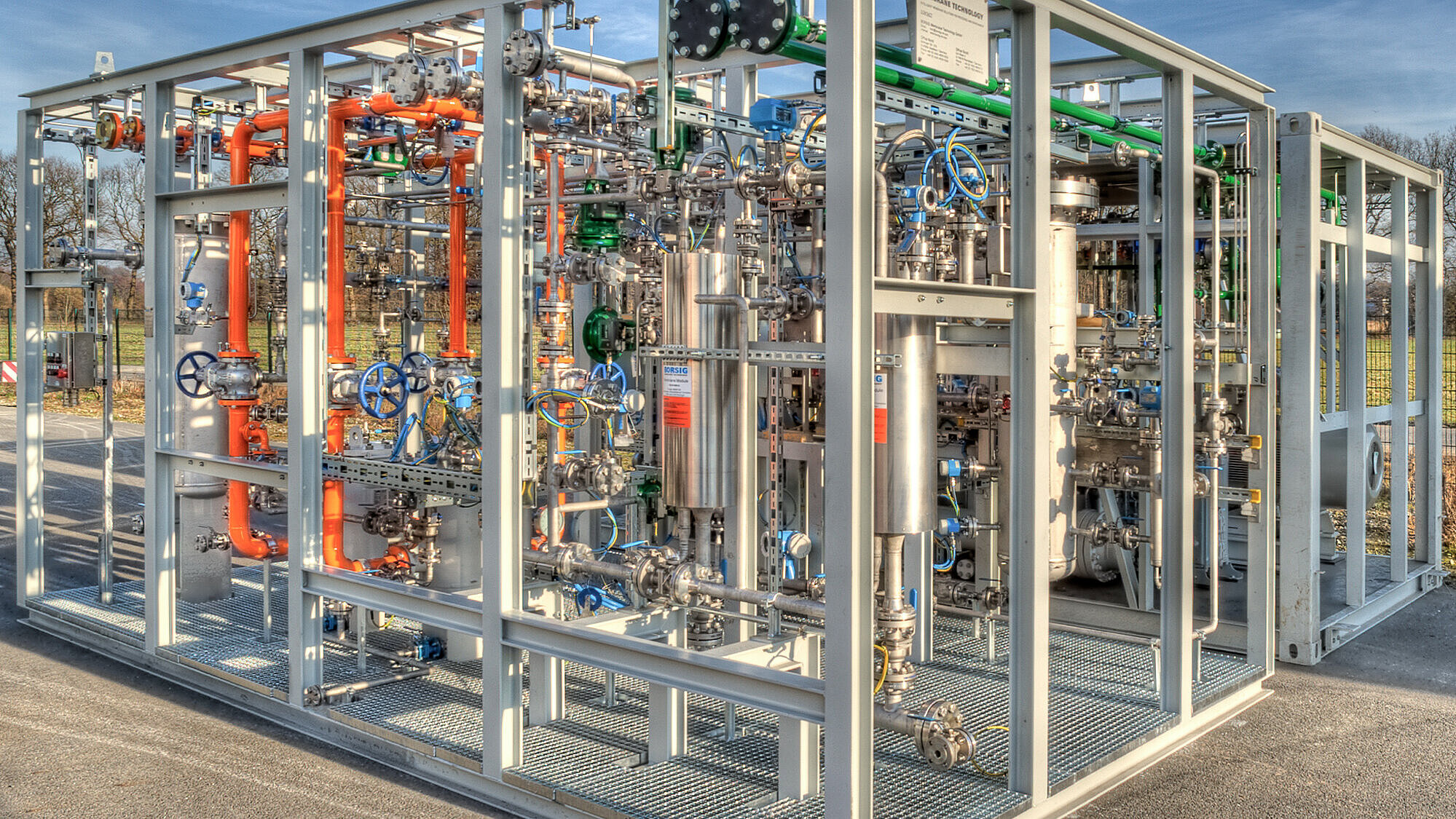

BORSIG Membrane Technology GmbH

Product recovery

units

Highest productivity and sustainability –

conserving and recovering resources can be that easy.